Advanced Polymer Processing Technologies for 2025: A Guide for Indian Manufacturers

Published on: January 18, 2025

Author: Team JITSY

Executive Summary

As we enter 2025, polymer processing technologies are undergoing rapid transformation, driven by automation, sustainability demands, and efficiency requirements. This comprehensive guide explores the latest advancements that Indian manufacturers should consider implementing to maintain competitive advantage and meet evolving market demands.

Key Technology Trends Reshaping Polymer Processing

1. Intelligent Extrusion Systems

The integration of AI and machine learning in extrusion processes is revolutionizing how manufacturers approach quality control and efficiency. Modern intelligent extrusion systems offer:

- Real-time process parameter optimization using advanced algorithms

- Predictive maintenance capabilities reducing downtime by up to 30%

- Automatic quality control systems with defect detection accuracy exceeding 98%

- Energy consumption optimization leading to 15-20% reduction in power usage

Indian manufacturers implementing these systems report average productivity increases of 25% within the first year of deployment.

2. Advanced In-Line Monitoring Systems

Contemporary polymer processing demands precise control and monitoring throughout the production cycle. Latest developments include:

- Integrated rheological sensors for real-time viscosity monitoring

- Advanced optical measurement systems for dimensional accuracy

- Thermal imaging cameras for temperature distribution analysis

- Ultrasonic testing systems for internal defect detection

These monitoring systems enable manufacturers to maintain consistent quality while reducing material waste by up to 40%.

3. Sustainable Processing Solutions

Environmental considerations are driving innovation in processing technologies:

- Advanced recycling-compatible processing systems

- Bio-based polymer processing modifications

- Energy-efficient heating and cooling systems

- Zero-waste production line solutions

Our research indicates that manufacturers implementing these sustainable solutions are seeing up to 25% reduction in carbon footprint and 15% decrease in operational costs.

Implementation Strategies for Indian Manufacturers

Assessment and Planning

Before implementing new technologies, manufacturers should:

- Conduct a comprehensive audit of existing systems

- Identify specific areas for improvement

- Calculate potential ROI for each technology

- Develop a phased implementation plan

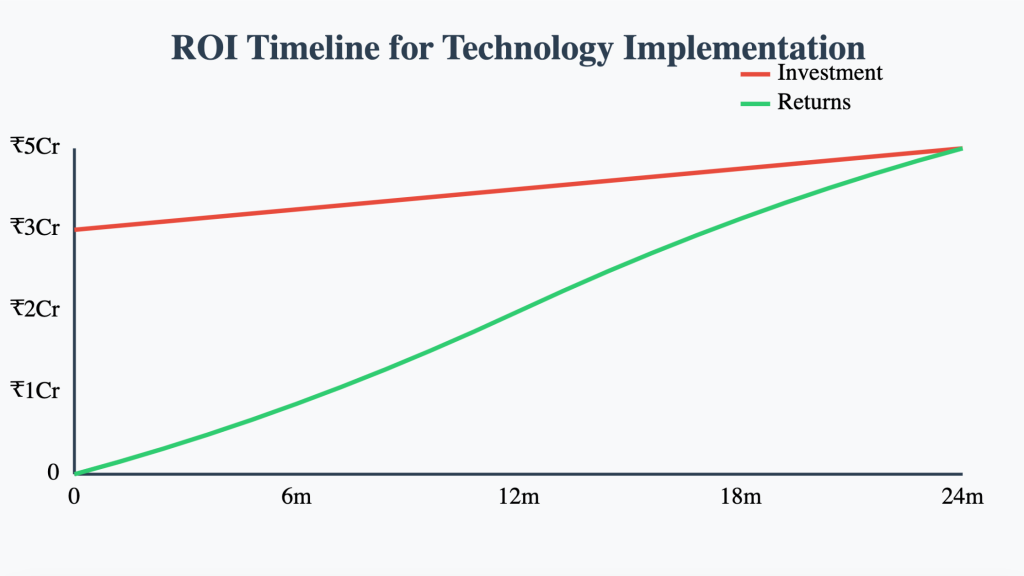

Cost Considerations

Investment ranges for key technologies:

- Basic automation upgrades: ₹50-75 lakhs

- Advanced monitoring systems: ₹1-2 crores

- Complete smart manufacturing solution: ₹3-5 crores

Training and Skill Development

Success in implementing advanced technologies requires:

- Comprehensive operator training programs

- Technical skill development workshops

- Partnership with technology providers for continuous support

- Regular assessment and certification of staff

Case Study: Success in Implementation

A leading polymer manufacturer in Gujarat implemented advanced processing technologies in 2024, resulting in:

- 35% increase in production efficiency

- 28% reduction in quality defects

- 22% decrease in energy consumption

- ROI achieved within 18 months

Future Outlook

The polymer processing industry is moving towards:

- Complete digital integration

- Advanced robotics and automation

- Sustainable processing solutions

- Smart quality control systems

Manufacturers who adopt these technologies early will be better positioned to:

- Meet increasing quality demands

- Compete in global markets

- Achieve sustainability goals

- Optimize operational costs

Conclusion

Advanced polymer processing technologies offer significant opportunities for Indian manufacturers to improve efficiency, quality, and sustainability. While the initial investment may be substantial, the long-term benefits in terms of reduced operational costs, improved quality, and increased competitiveness make it a crucial consideration for forward-thinking manufacturers.

About the Author: This article is written by the technical team at JITSY, with insights from industry experts and manufacturing consultants.

*References:

- Indian Plastics Federation Technology Report 2024

- Polymer Processing Industry Survey 2024

- Manufacturing Technology Centre Research Data*

Latest Articles

Small vs. Large Manufacturers: The Procurement Divide That’s Holding India Back

India cannot afford to grow unequally. If the vision is to become a global manufacturing powerhouse, we must ensure that procurement works for everyone – not just the big players.

The Great Procurement Divide: Why Your Best Engineers Make Your Worst Buyers

“He knows everything about polymers—so let him handle the purchase too.”

Copy-Paste vs. Innovation

Is playing it safe actually the riskiest strategy? The uncomfortable truth about innovation avoidance in Indian manufacturing

The Credit Cycle Shift: Why 30-Day Payments Are Winning Hearts (and Wallets)

The Credit Cycle Shift: Why 30-Day Payments Are Winning Hearts (and Wallets)

The Great Inventory Debate

Just-in-Time vs. Just-in-Case After COVID

The 0.1% That Destroys the 99.9%: Why Documentation in B2B Trade Isn’t Optional Anymore

“Sir, you have my word.”

“It’s done. Dispatch tomorrow.”

The Growing Crisis of Non-Compliance in India’s Polymer Supply Chain: Protecting Your Business

The Hidden Danger in Your Raw Material Procurement. Manufacturing sectors face increased scrutiny…

Complete Documentation Isn’t Optional – It’s Critical

Six months later, you receive a notice from the GST department that sends a chill down your spine…

5 Ways to Optimise Your Polymer Supply Chain

Explore five proven approaches that can transform your polymer supply chain…

Experience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India