Expandable Microspheres

Advanced Lightweighting Technology

Revolutionize your material design with Expandable Microspheres, the high-performance lightweight fillers that deliver controlled expansion, superior insulation, and unmatched versatility across multiple grades for optimized processing and product performance.

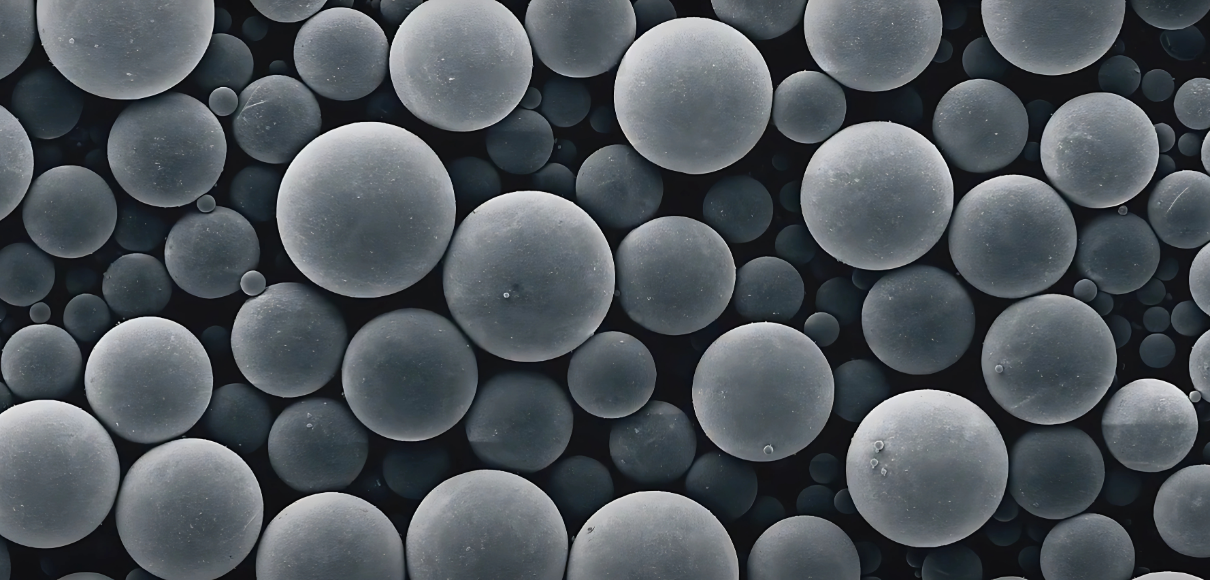

Understanding Expandable Microspheres

Expandable microspheres are innovative, thermoplastic hollow spheres filled with hydrocarbon-based blowing agents. When exposed to heat, they expand dramatically, forming closed-cell structures that reduce density and improve insulation without compromising strength. These microspheres are used as lightweight fillers, blowing agents, and surface modifiers in a wide range of polymer applications.

The secret of their performance lies in their engineered shell and encapsulated gas. Upon heating, the gas expands and softens the polymer shell, causing the microsphere to increase in volume by up to 60 times. This expansion provides a highly controlled and uniform foaming effect—ideal for lightweighting, texture control, and energy absorption across industries.

Expandable microspheres are valued for their low density, chemical resistance, excellent process compatibility, and environmentally friendly formulation. They offer a smart solution for replacing heavier, bulkier fillers and are widely used to reduce material consumption and improve product functionality.

Expandable Microspheres Commercial Grades

High-Temperature Grade

Designed for processes requiring higher activation temperatures, this grade offers:

- Controlled expansion at elevated temperatures (150–220°C)

- Ideal compatibility with engineering polymers

- Excellent thermal stability and dispersion

- Perfect for extrusion and high-temperature molding applications

The high-temperature grade is particularly effective in automotive plastics, engineered foams, and high-performance sealants.

Low-Temperature Grade

Optimized for processes with lower processing heat, our low-temperature grade provides:

- Expansion temperatures as low as 80°C

- Fast response for quick-cycle manufacturing

- Excellent for low-temp thermoplastics and water-based systems

- Uniform expansion for smooth surface finishes

This grade is ideal for coatings, paper, packaging foams, and water-based formulations.

Pre-Expanded Microspheres

These are thermally expanded microspheres used as ultra-lightweight fillers. Key features include:

- No further heat expansion required

- Extremely low bulk density

- Improved texture and surface properties

- High compressibility and recovery

Pre-expanded microspheres are widely used in synthetic leather, sealants, spackling compounds, and elastomeric coatings.

Surface-Modified Grade

Formulated with tailored surface treatments to enhance compatibility with specific matrices. This grade delivers:

- Improved dispersion in polar and non-polar systems

- Enhanced bonding with resins and adhesives

- Customizable interaction with target substrates

- Excellent performance in composite and reactive systems

Used in specialty coatings, adhesives, and engineered thermosets.

Expandable Microspheres Applications in Modern Industry

Expandable microspheres serve as a go-to solution in numerous industries. In the automotive sector, they reduce part weight while maintaining strength in applications like body fillers, sealants, and underbody coatings. Their ability to improve impact resistance and lower weight makes them a perfect fit for OEMs pursuing fuel efficiency.

In construction materials, microspheres are used to produce lightweight fillers, insulating foams, and textured wall coatings. Their contribution to lower thermal conductivity and reduced material usage translates directly into energy and cost savings.

The coatings and adhesives industry benefits from microspheres' ability to reduce density, improve texture, and add compressibility to surfaces—ideal for wall paints, elastomeric roof coatings, and caulks.

In consumer goods, from shoe soles to cosmetic packaging, microspheres offer comfort, reduced weight, and aesthetic enhancements, making products lighter, softer, and more energy-efficient to produce.

Safety Note:

Expandable microspheres must be handled in accordance with standard safety guidelines for thermoplastic additives. Always consult technical datasheets and safety documentation provided for each grade. Our team is available to support safe and effective integration into your production lines.

Features

- Lightweight Filler

- High Expansion Ratio

- Thermal Insulation

- Versatile Activation Range

- Excellent Dispersion

- Improves Surface Texture

- Reduces Raw Material Use

- Chemical Stability

Applications

Lightweight fillers and sealants

Lightweight fillers and sealants Floor and roof coatings

Floor and roof coatings Textured decorative coatings

Textured decorative coatings Adhesives and Sealants

Adhesives and Sealants Footwear and Consumer Goods

Footwear and Consumer Goods Synthetic Leather and Textiles

Synthetic Leather and TextilesExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India