Products

Homo, Impact/CP & Random Copolymer for Industrial Manufacturing

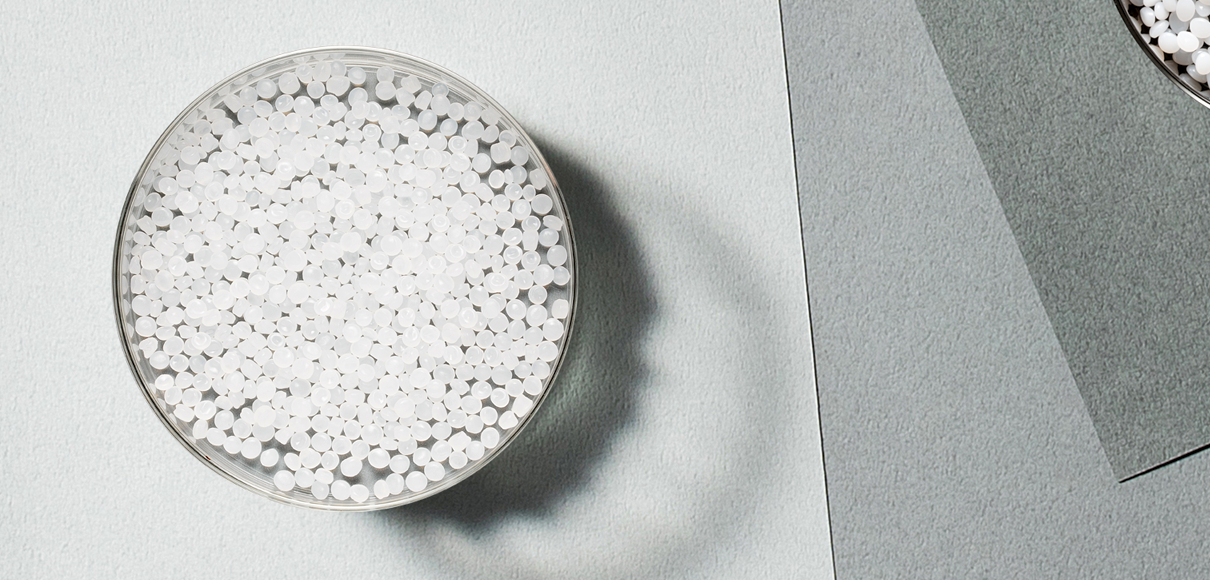

Polypropylene (PP) is a versatile thermoplastic polymer widely used across Indian manufacturing for its excellent balance of strength, stiffness, chemical resistance, and easy processing. It is lightweight, cost‑effective, and suitable for high‑volume production, which makes it a preferred choice for industries such as footwear, packaging, consumer goods, automotive, wire and cable, and many more. At JITSY, we supply high‑quality PP grades from trusted Indian and global manufacturers with transparent, real‑time pricing and reliable just‑in‑time deliveries.

PP from JITSY is known for consistent quality and predictable performance. It offers good mechanical strength, dimensional stability, and resistance to many chemicals, detergents, and solvents, while still being easy to process on standard injection moulding, extrusion, blow moulding, and thermoforming machines. Because PP is recyclable and lightweight, it also helps manufacturers reduce material usage and support more sustainable production without compromising on performance.

PP Homopolymer (PP Homo)

PP Homopolymer is the most common and widely used form of polypropylene. It is a high‑crystallinity grade that offers high stiffness, good tensile strength, and excellent chemical resistance. This combination makes PP Homo ideal for rigid products where strength and shape retention are important.

Manufacturers use PP Homo for household and consumer items, rigid packaging containers, caps and closures, industrial components, appliance parts, and woven applications such as raffia, tapes, and sacks. In many factories, PP Homo is the preferred choice for items that must remain dimensionally stable under load and moderate heat, while still being lightweight and economical.

In day‑to‑day production, PP Homopolymer helps reduce part weight without sacrificing rigidity, which is especially useful in packaging, logistics, and consumer goods. Its resistance to moisture and many chemicals makes it suitable for products that come into contact with detergents, cleaning agents, and various industrial environments. Because it flows well during processing, PP Homo supports faster cycle times and consistent part quality, which is critical for high‑volume manufacturing.

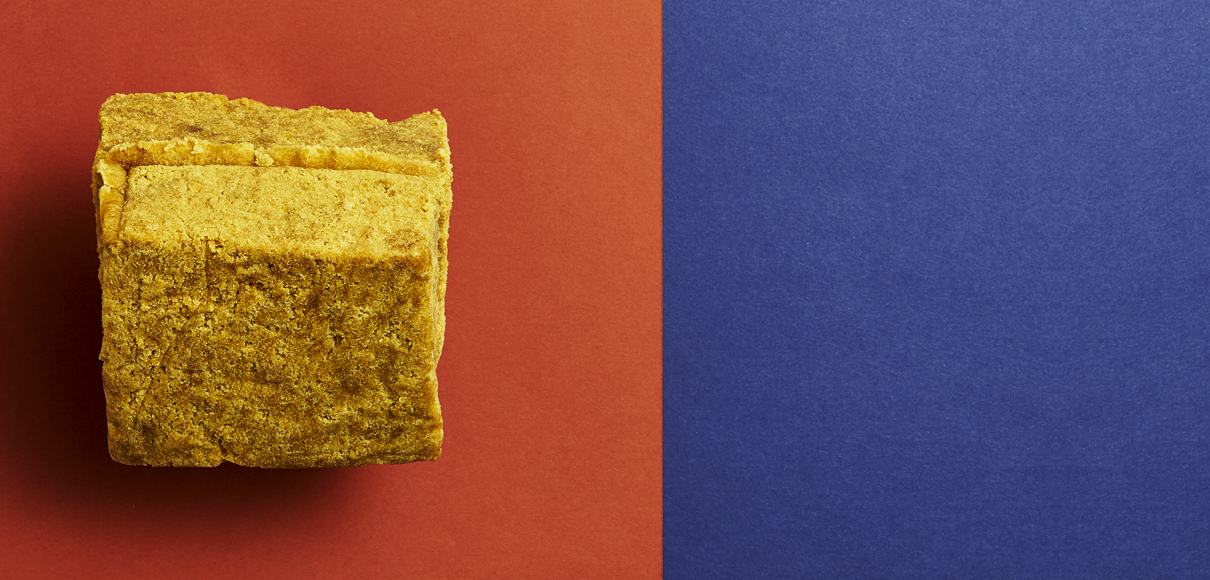

PP Impact Copolymer (PP Impact / PP CP)

PP Impact Copolymer, often called PP CP, is designed for applications where higher impact strength and toughness are required, especially at lower temperatures. It combines the stiffness of PP Homopolymer with a rubber phase that improves impact resistance, making it suitable for more demanding and heavy‑duty parts. This grade is widely used in automotive components such as bumpers, dashboards, interior trims, battery cases, and under‑the‑hood parts, as well as industrial crates, pallets, containers, and electrical appliance housings.

In practical use, PP Impact Copolymer offers a strong balance between rigidity and toughness. It can handle rough handling, stacking, and repeated use, which is why it is commonly chosen for logistics and industrial packaging. The material maintains good processability and supports efficient moulding cycles, allowing manufacturers to produce robust parts at scale. For sectors like automotive and industrial equipment, PP CP helps achieve durable, impact‑resistant components while still keeping overall part weight and cost under control.

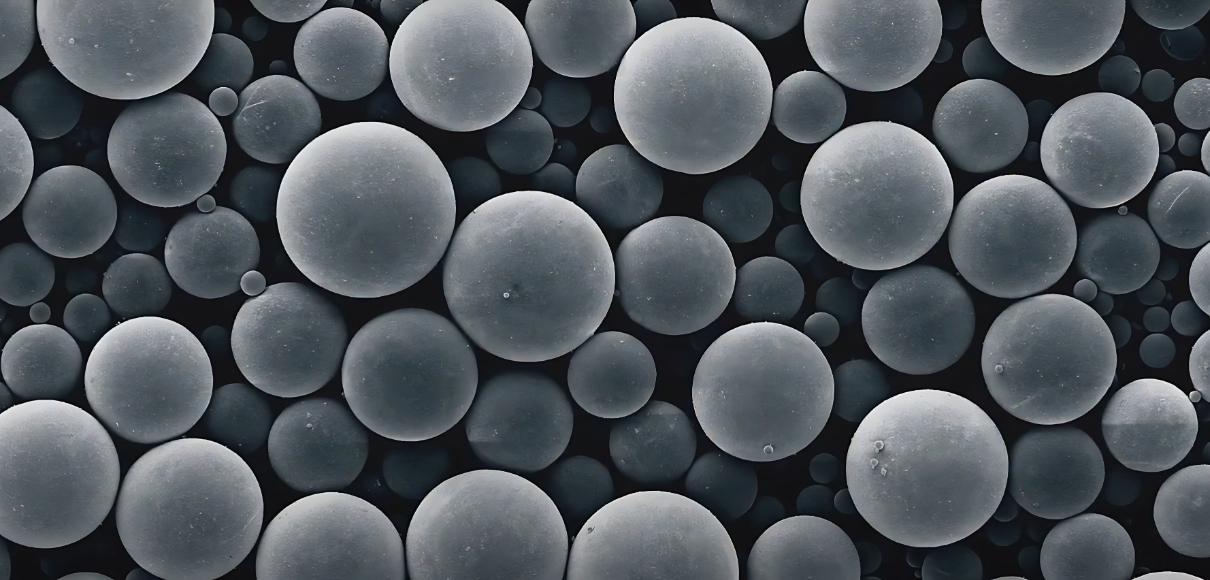

PP Random Copolymer (PP Random)

PP Random Copolymer is known for its excellent clarity, transparency, and good impact strength at room temperature. It is the preferred choice when appearance and aesthetics are important along with performance. PP Random is commonly used for transparent food containers, houseware products, clear bottles and jars, cosmetic and personal care packaging, and certain medical or laboratory items depending on the grade. Its high gloss and clarity help brands present a premium look, while the material still offers the chemical resistance and heat performance associated with polypropylene.

In manufacturing, PP Random allows producers to create thin‑wall, clear parts that look attractive on shelves and are comfortable for end‑users to handle. Many grades are suitable for hot‑fill or microwave‑safe applications, making them ideal for modern food packaging and kitchenware, subject to specific regulatory and technical approvals. The combination of transparency, impact strength, and processability makes PP Random a strong choice for any application where both design and durability matter.

Advantages of Using PP in Manufacturing

Across all three categories—Homo, Impact/CP, and Random—PP offers a strong performance‑to‑cost ratio. It is lightweight, which reduces shipping and handling costs and helps manufacturers lower material consumption per part. Its broad chemical resistance makes it suitable for contact with many everyday substances, from household cleaners to industrial chemicals, depending on the grade. PP can be processed on standard plastic processing equipment, which means factories can switch or scale PP production without major changes to their existing setup. Because PP is recyclable, it also fits well into sustainability and circular economy initiatives, helping manufacturers align with evolving regulatory and customer expectations.

PP Supply with JITSY

JITSY focuses on providing reliable PP supply with transparent pricing, fast dispatch, and complete visibility through the JITSY app. Manufacturers can view real‑time PP prices, track orders, and access technical details to choose the right PP Homo, PP Impact/CP, or PP Random grade for their application. With strong partnerships across leading Indian and global producers and a logistics network designed for just‑in‑time deliveries, JITSY helps factories maintain smooth, predictable procurement of polypropylene for daily production.

Experience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India

Copyright © 2025, JITSY, All Rights Reserved

JITSY is a proprietary platform owned & operated by Rudranarayana Trade Solutions Private Limited