Nitrile Butadiene Rubber : NBR

Advanced Oil-Resistant Rubber Technology

Transform your critical applications with Nitrile Butadiene Rubber (NBR), the specialized synthetic rubber that delivers outstanding resistance to oils, fuels, and chemicals while maintaining excellent mechanical properties.

Understanding NBR (Nitrile Butadiene Rubber)

Nitrile Butadiene Rubber represents a significant advancement in specialty elastomer technology, distinguished by its exceptional resistance to oils and petroleum-based fluids. The secret to NBR's performance lies in its molecular structure, which combines acrylonitrile and butadiene units in precisely controlled ratios. The acrylonitrile content directly influences the rubber's oil resistance – higher levels provide enhanced resistance to non-polar substances, while the butadiene component contributes to the material's flexibility and low-temperature performance.

Understanding the relationship between acrylonitrile content and performance is crucial for optimal material selection. As acrylonitrile levels increase, oil resistance improves, but low-temperature flexibility decreases. This fundamental principle guides the development of different NBR grades, allowing manufacturers to select the perfect balance for their specific applications. The material's unique chemical structure also provides excellent resistance to heat aging and maintains its properties over a wide temperature range.

NBR Classifications

Standard Nitrile Grades

Our standard NBR grades cover a range of acrylonitrile contents from 18% to 50%. Through careful control of the polymerization process, we produce varieties that balance oil resistance with flexibility. These grades serve as the foundation for many industrial applications, offering reliable performance in moderately demanding environments. The varying acrylonitrile contents enable users to select the optimal grade based on specific oil resistance requirements and operating conditions.

Carboxylated Nitrile Grades (XNBR)

Our carboxylated grades represent an advanced development in NBR technology. By incorporating carboxyl groups into the polymer backbone, these grades offer enhanced strength properties and improved abrasion resistance. The modified chemical structure provides superior compatibility with fillers and better adhesion characteristics, making these grades particularly valuable in demanding applications requiring high strength and wear resistance.

Low-Temperature Grades

Developed specifically for challenging cold environments, our low-temperature NBR grades maintain flexibility at reduced temperatures while providing necessary oil resistance. These specialized products achieve their performance through optimized acrylonitrile content and careful control of polymer architecture. The balanced composition ensures reliable performance in applications where standard grades might become too stiff.

Pre-Crosslinked Grades

Our pre-crosslinked NBR grades offer unique processing advantages and improved physical properties. Through controlled partial crosslinking during production, these grades provide enhanced processing safety and reduced tendency toward scorching. The pre-crosslinked structure contributes to improved compression set and better retention of physical properties at elevated temperatures.

Applications in Modern Industry

NBR demonstrates its versatility across numerous demanding industrial sectors. In the automotive industry, it serves as the primary material for oil seals, fuel hoses, and various gaskets. The material's resistance to motor oils, fuels, and other automotive fluids makes it indispensable in modern vehicle systems. Its ability to maintain properties over long periods of exposure to these fluids ensures reliable long-term performance.

The oil and gas industry extensively utilizes NBR for manufacturing seals, gaskets, and hoses exposed to aggressive environments. Whether in drilling operations or processing facilities, NBR compounds provide the necessary resistance to hydrocarbon-based fluids while maintaining structural integrity. The material's heat resistance and aging properties ensure extended service life in these demanding applications.

In the industrial equipment sector, NBR plays a crucial role in developing reliable sealing solutions. From hydraulic systems to pneumatic equipment, NBR components ensure efficient operation by preventing fluid leakage and maintaining system integrity. The material's resistance to industrial oils and greases, combined with good mechanical properties, makes it the preferred choice for many sealing applications.

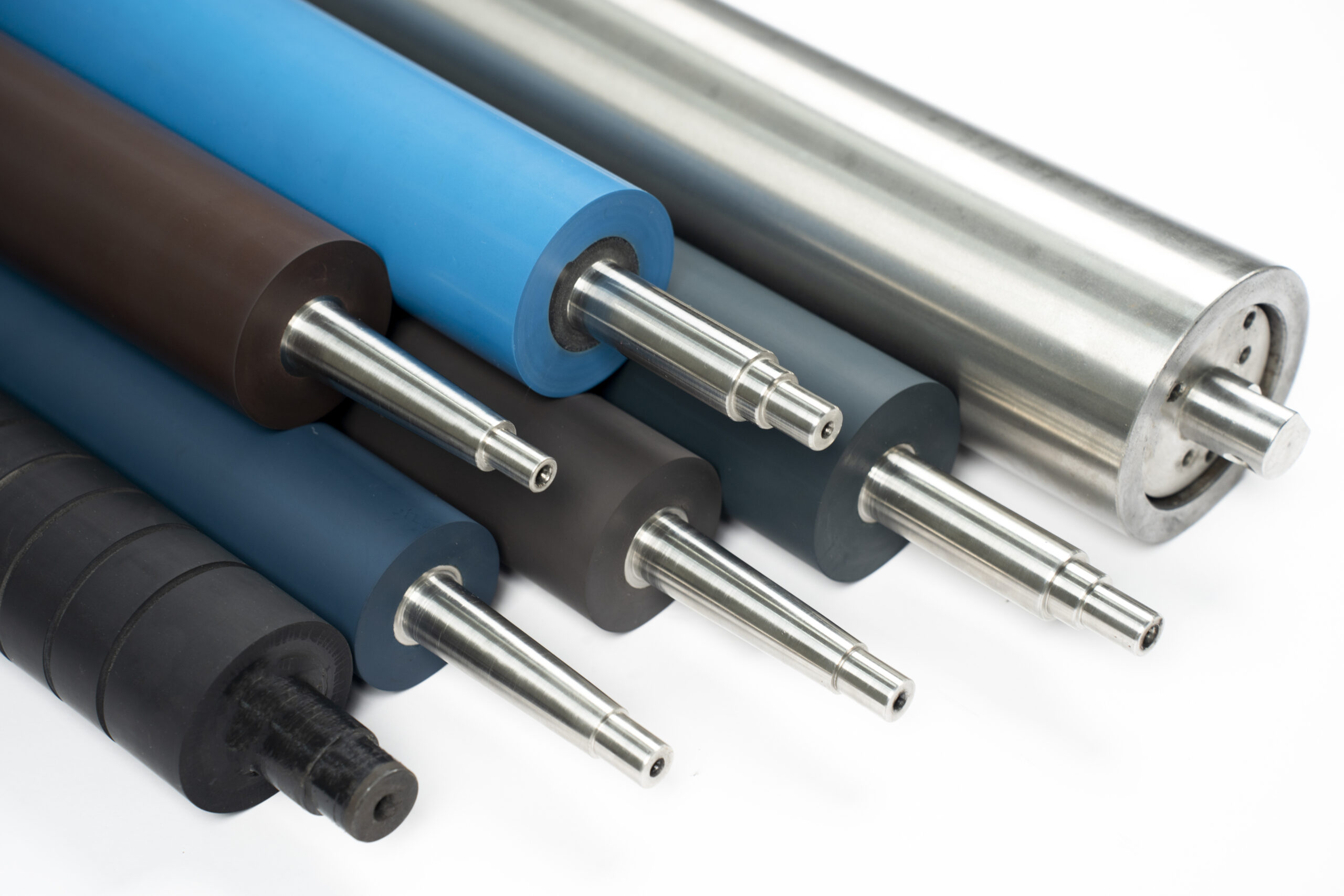

The printing industry showcases NBR's importance through applications in roller coverings and printing blankets. The material's resistance to printing inks and cleaning solvents, coupled with good dynamic properties, ensures consistent performance in printing operations. Its ability to maintain dimensional stability while exposed to aggressive chemicals makes it particularly valuable in this precision application.

Features

- Exceptional oil and fuel resistance

- Controlled acrylonitrile content

- Excellent heat aging properties

- Good mechanical strength

- Temperature stability

- Chemical resistance

- Processing versatility

- Reliable sealing properties

Applications

Automotive seals and hoses

Automotive seals and hoses Oil field equipment

Oil field equipment Hydraulic seals

Hydraulic seals Printing rollers

Printing rollers Industrial gaskets

Industrial gaskets Fuel system components

Fuel system components Wire and cable jacketing

Wire and cable jacketing Roll covering applications

Roll covering applicationsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India