Styrene Butadiene Rubber : SBR

Engineering Performance in Synthetic Rubber Solutions

Transform your rubber applications with Styrene Butadiene Rubber (SBR), the versatile synthetic rubber that combines outstanding wear resistance with superior processing characteristics.

Understanding SBR (Styrene Butadiene Rubber)

Styrene Butadiene Rubber represents a significant achievement in synthetic rubber technology, emerging as one of the most widely used elastomers globally. Its molecular structure, consisting of styrene and butadiene units in carefully controlled ratios, provides an exceptional balance of properties. The distribution and arrangement of these molecular building blocks determine the final properties of the rubber, allowing manufacturers to tailor characteristics for specific applications.

The success of SBR lies in its ability to deliver consistent performance across a wide temperature range while maintaining excellent abrasion resistance. Through careful control of polymerization conditions and monomer ratios, SBR offers manufacturers the flexibility to achieve specific performance characteristics. The material's inherent stability and compatibility with various compounding ingredients make it particularly valuable in developing customized rubber formulations.

SBR Classifications

Emulsion SBR (E-SBR)

Our emulsion polymerized grades represent the traditional and most widely used form of SBR. Through advanced emulsion polymerization technology, we produce varieties with different styrene contents and oil extension levels. These grades excel in applications requiring balanced properties and easy processing. The cold polymerized grades offer superior strength and wear resistance, while hot polymerized varieties provide enhanced processing characteristics.

Solution SBR (S-SBR)

Our solution polymerized grades showcase the latest advancements in synthetic rubber technology. These grades feature precisely controlled molecular structure and distribution, resulting in superior dynamic properties. The careful control over microstructure enables exceptional performance in demanding applications, particularly in modern tire manufacturing where reduced rolling resistance and enhanced wet grip are crucial.

Oil Extended Grades

Developed for optimized processing and cost-effectiveness, our oil extended grades incorporate carefully selected process oils during production. These grades offer improved processing characteristics and lower compound costs while maintaining essential performance properties. The controlled oil extension enables higher filler loading capabilities and easier mixing in downstream operations.

High Styrene Grades

Our high styrene content grades cater to applications requiring increased hardness and improved processing. These specialized products deliver enhanced stiffness and dimensional stability while maintaining good elastomeric properties. The higher styrene content enables better compatibility with polystyrene and improved printing characteristics in specific applications.

Applications in Modern Industry

SBR demonstrates its versatility across numerous industrial sectors. In the tire industry, it serves as the primary polymer for passenger car tire treads. When properly compounded, SBR provides the optimal balance of wet grip, wear resistance, and rolling resistance required for modern tire performance. The material's ability to accept high filler loadings while maintaining good processing characteristics makes it particularly valuable in this demanding application.

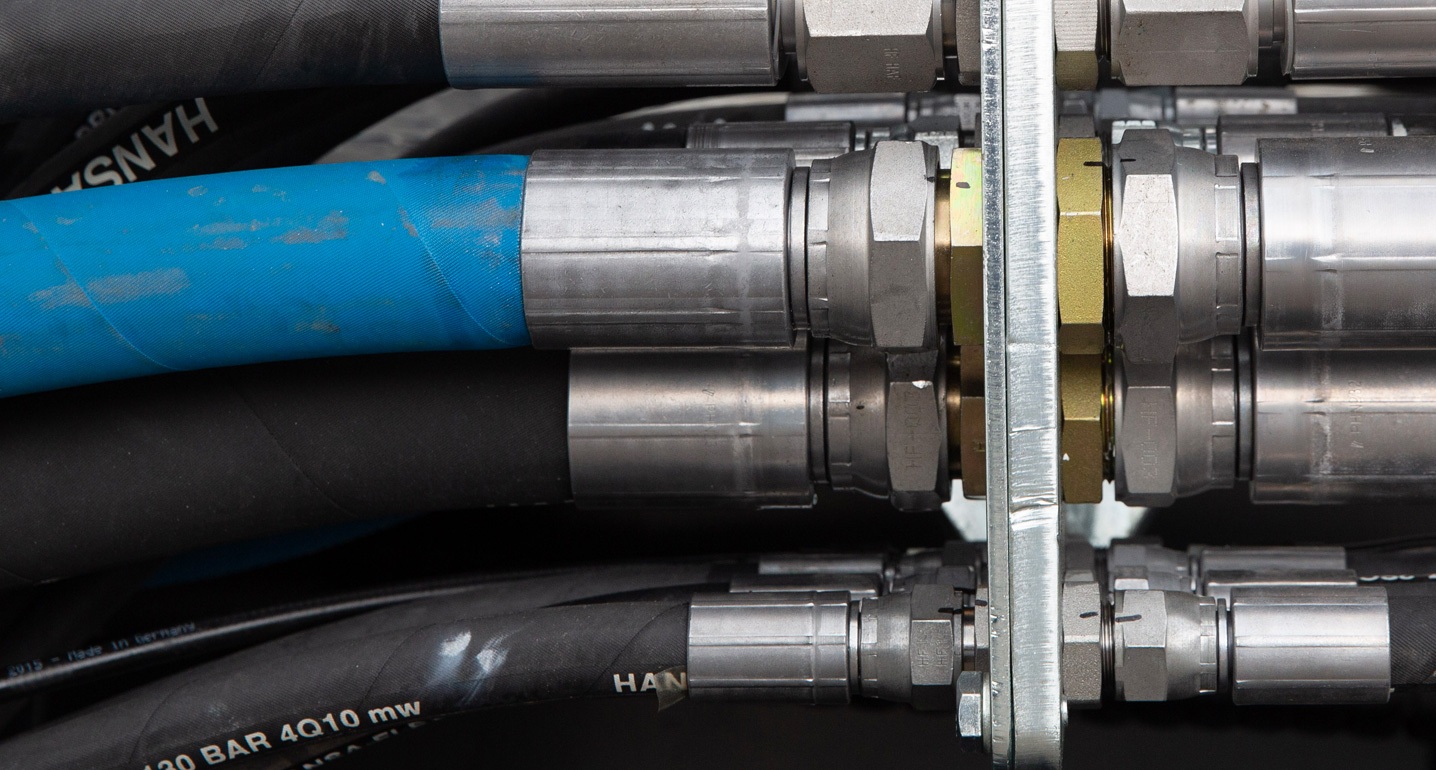

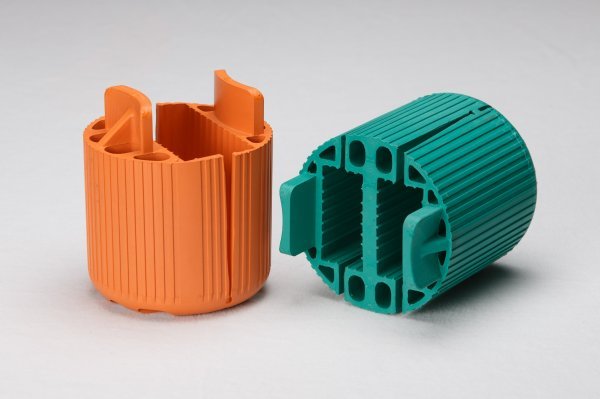

The technical rubber goods sector extensively utilizes SBR for manufacturing conveyor belts, hoses, and various mechanical goods. The material's excellent abrasion resistance and aging properties ensure long service life in these applications. Its compatibility with other polymers enables manufacturers to develop optimized blends for specific performance requirements.

In the footwear industry, SBR plays a crucial role in developing durable sole compounds. Its excellent wear resistance and flex properties make it ideal for both athletic and casual footwear applications. The material's ability to be colored and its good adhesion properties provide designers with flexibility in creating innovative footwear solutions.

The construction sector showcases SBR's importance through applications in flooring, roofing, and sealing systems. Whether used in modified bitumen or as a polymer modifier, SBR enhances the durability and performance of construction materials. Its weather resistance and stability make it particularly suitable for outdoor applications.

Features

- Outstanding wear resistance

- Excellent processing characteristics

- Good aging properties

- High filler acceptance

- Consistent performance

- Temperature stability

- Versatile compounding options

- Cost-effective performance

Applications

Tire compounds

Tire compounds Conveyor belts

Conveyor belts Industrial hoses

Industrial hoses Shoe soles

Shoe soles Mechanical goods

Mechanical goods Modified bitumen

Modified bitumen Adhesive systems

Adhesive systems Technical molded goods

Technical molded goodsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India