Titanium Dioxide : TiO2

The Premium White Pigment for Superior Opacity

Transform your products with Titanium Dioxide (TiO2), the industry-leading white pigment that delivers unmatched opacity, brightness, and UV protection across diverse applications.

Understanding TiO2 (Titanium Dioxide)

Titanium Dioxide represents the gold standard in white pigments, offering superior opacity and whiteness that sets it apart from all other white pigments in industrial use. This inorganic compound's exceptional performance stems from its unique crystal structure and high refractive index, which enable it to scatter visible light more effectively than any other white pigment. Through sophisticated manufacturing processes, both anatase and rutile crystal forms are produced, each optimized for specific applications and performance requirements.

The material's extraordinary effectiveness as a white pigment comes from its optimal particle size distribution, typically centered around 0.3 microns, which maximizes light scattering efficiency. This characteristic, combined with its high refractive index, enables titanium dioxide to provide excellent hiding power even at relatively low concentrations. Additionally, its chemical inertness and UV-resistant properties make it an ideal choice for applications requiring long-term durability and weather resistance.

Understanding Titanium Dioxide Grades and Properties

Rutile grades dominate commercial applications, offering superior opacity and UV resistance compared to anatase variants. These grades undergo surface treatments designed to enhance dispersibility and durability in specific applications. Aluminum and silicon oxide treatments improve weather resistance and dispersibility in paints, while organic surface treatments enhance compatibility in plastic applications.

Paint-grade titanium dioxide features carefully controlled particle size distributions and surface treatments optimized for different paint systems. Interior grades focus on maximum opacity and brightness, while exterior grades incorporate additional treatments to ensure weather durability and chalk resistance. The surface chemistry is precisely engineered to ensure optimal compatibility with various resin systems, from water-based to solvent-based formulations.

Plastic-grade variants are specifically engineered for excellent dispersibility in polymer systems. These grades often feature specialized surface treatments that enhance processing characteristics and prevent agglomeration during high-temperature processing. The careful control of particle size distribution ensures optimal balance between opacity and processing properties in the final compound.

Industry Applications and Performance

The paint and coatings industry represents the largest consumer of titanium dioxide, where its superior hiding power and brightness are essential for high-quality finishes. In architectural paints, it provides excellent coverage and long-term durability, while industrial coatings benefit from its chemical inertness and UV resistance. The material's ability to maintain its brightness and color stability over time makes it invaluable in premium coating applications.

Plastic manufacturers rely on titanium dioxide for both white coloration and UV protection in their products. Its high thermal stability allows processing across a wide range of temperatures without degradation, while its chemical inertness ensures long-term performance in the final product. From packaging materials to durable outdoor products, titanium dioxide provides essential functionality beyond simple white coloration.

The paper industry utilizes titanium dioxide to achieve high brightness and opacity in premium grades. Its superior light scattering efficiency enables the production of high-quality printing papers with excellent printability and visual appeal. The material's chemical stability ensures consistent performance throughout the paper's lifecycle.

Cosmetic and pharmaceutical applications benefit from titanium dioxide's safety profile and excellent UV protection properties. In sunscreens, it serves as a physical UV blocker, while in cosmetics, it provides opacity and brightness in various formulations. Its inert nature makes it particularly suitable for these sensitive applications.

Features

- Exceptional opacity

- Superior whiteness and brightness

- Excellent UV resistance

- High chemical stability

- Strong hiding power

- Temperature resistance

- Non-toxic nature

- Light scattering efficiency

- Weathering durability

- Broad compatibility

Applications

Architectural paints

Architectural paints Industrial coatings

Industrial coatings Paper and board

Paper and board Cosmetics

Cosmetics Pharmaceuticals

Pharmaceuticals Sunscreen formulations

Sunscreen formulations Printing inks

Printing inks Food coloring

Food coloring Synthetic fibers

Synthetic fibers Ceramic glazes

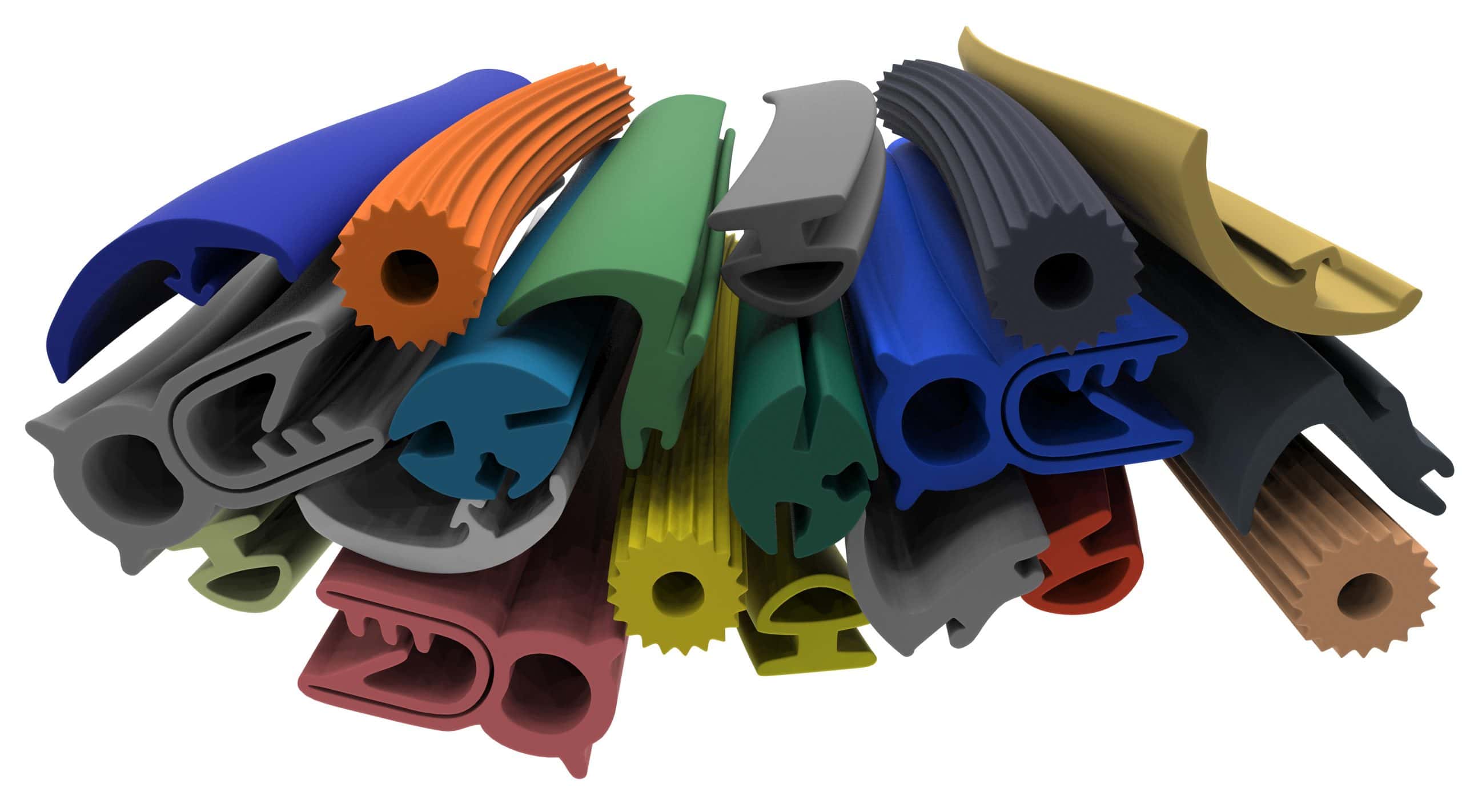

Ceramic glazes Rubber products

Rubber productsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India