Natural Rubber

The Sustainable Choice for Premium Elastic Applications

Transform your products with Natural Rubber (NR), the renewable elastomer that sets the benchmark for resilience, elasticity, and environmental sustainability in rubber applications.

Understanding Natural Rubber

Natural Rubber represents nature's gift to industrial applications, harvested primarily from Hevea Brasiliensis trees through a sophisticated tapping process. This remarkable material consists of cis-1,4-polyisoprene, nature's perfect polymer chain structure that delivers unmatched elasticity and resilience. The unique molecular configuration of natural rubber provides superior dynamic properties that synthetic alternatives still strive to match, making it irreplaceable in many demanding applications.

The raw material undergoes careful processing from field latex to commercial grades, preserving its inherent properties while enabling customization for specific applications. Through controlled coagulation and sophisticated processing techniques, natural rubber is transformed into various commercial forms, each optimized for specific end uses. The material's ability to strain crystallize under deformation contributes to its exceptional strength and wear resistance, particularly valuable in high-performance applications.

Understanding Natural Rubber Grades and Properties

Ribbed Smoked Sheets (RSS) represent the premium grade of natural rubber, produced through a carefully controlled smoking process that ensures optimal cleanliness and consistency. These grades are classified from RSS-1 to RSS-5, with RSS-1 offering the highest purity and cleanliness levels. The smoking process not only dries the rubber but also imparts antioxidant properties that enhance storage stability and processing characteristics.

Technically Specified Rubber (TSR) grades offer manufacturers precise control over properties through standardized processing and testing. These grades are classified based on dirt content, ash content, nitrogen content, plasticity retention index (PRI), and other technical parameters. TSR grades range from TSR-CV for premium applications to TSR-20 for general-purpose use, enabling manufacturers to select the exact grade needed for their specific requirements.

Latex concentrates serve specialized applications requiring liquid natural rubber. These grades undergo centrifugation to increase rubber content from approximately 30% in field latex to 60% or higher. The concentrated latex can be further processed to remove non-rubber constituents, producing specialized grades for dipping applications, foam production, and adhesive manufacturing.

Industry Applications and Performance

The tire industry remains the largest consumer of natural rubber, particularly for commercial vehicle tires where its superior dynamic properties are essential. Natural rubber's exceptional fatigue resistance and heat buildup characteristics make it irreplaceable in truck tire treads and aircraft tires. The material's strain crystallization behavior contributes to excellent tear resistance and overall durability under severe operating conditions.

Engineering applications benefit from natural rubber's superior vibration damping properties. Anti-vibration mounts, bridge bearings, and seismic isolation systems rely on natural rubber's ability to absorb energy while maintaining structural integrity over long service periods. The material's low heat buildup characteristics ensure reliable performance under repeated stress cycles.

In medical applications, natural rubber latex continues to play a vital role despite the emergence of synthetic alternatives. Its unique combination of barrier properties, elasticity, and tactile sensitivity makes it particularly valuable in examination gloves and specialized medical devices. Advanced processing techniques have enabled the production of low-protein variants that address allergenicity concerns while maintaining superior performance characteristics.

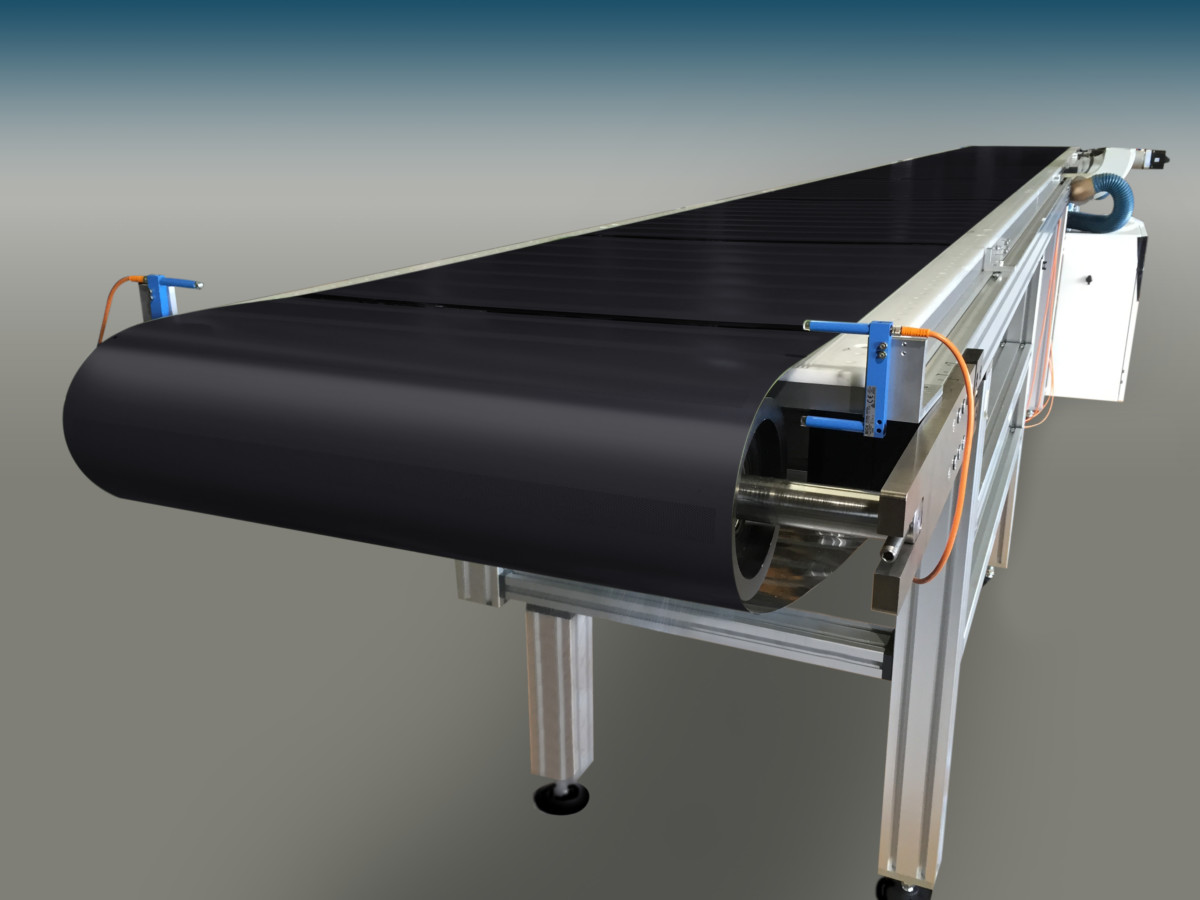

Construction and mining industries utilize natural rubber's exceptional properties in conveyor belts, mining equipment components, and specialized seals. The material's ability to withstand severe operating conditions while maintaining flexibility and resilience makes it indispensable in these demanding applications.

Features

- Superior dynamic properties

- Excellent tear resistance

- High tensile strength

- Outstanding elasticity

- Natural origin and sustainability

- Exceptional strain crystallisation

- Low heat buildup

- Superior processing flexibility

- Excellent air impermeability

- High resilience and rebound

Applications

Tyres

Tyres Anti-vibration mounts

Anti-vibration mounts Medical gloves and devices

Medical gloves and devices Conveyor belts

Conveyor belts Engineering mounts

Engineering mounts Seismic isolation systems

Seismic isolation systems Industrial seals

Industrial seals Adhesives and sealants

Adhesives and sealants Sports goods and equipment

Sports goods and equipment Footwear components

Footwear components Rubber Tracks

Rubber TracksExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India