Polyolefin Elastomer : POE

The Advanced Solution for Flexible Polyolefin Applications

Transform your products with Polyolefin Elastomer (POE), the innovative material that brings rubber-like flexibility to polyolefin applications while maintaining excellent processing characteristics.

Understanding POE (Polyolefin Elastomer)

Polyolefin Elastomer represents a breakthrough in polymer technology, bridging the gap between plastics and rubber. This advanced material is produced through metallocene catalysis, resulting in a highly controlled molecular structure that delivers consistent performance and superior properties. POE's unique molecular architecture combines crystalline and amorphous regions, providing excellent flexibility while maintaining compatibility with various polyolefins. The material offers outstanding low-temperature impact resistance and enhanced flexibility without compromising processability, making it an ideal choice for applications requiring soft-touch characteristics and improved impact performance.

Unlike traditional elastomers, POE offers exceptional compatibility with polyolefins, particularly polyethylene and polypropylene. This compatibility enables manufacturers to achieve precise property modifications in compounds and blends. The material's controlled molecular weight distribution ensures consistent processing and end-product performance, while its elastomeric nature provides excellent recovery properties and long-term flexibility retention.

Understanding POE Classifications and Properties

In the general-purpose category, POE grades feature density ranges from 0.857 to 0.875 g/cm³, offering a balance of flexibility and processability. These grades find extensive use in automotive applications, packaging films, and general polymer modification. The molecular structure can be fine-tuned during production to achieve specific performance characteristics, such as enhanced low-temperature flexibility or improved heat resistance.

Impact modification grades incorporate optimized molecular weight and comonomer distribution, specifically designed to enhance the impact strength of rigid polyolefins. These grades typically feature density ranges from 0.860 to 0.870 g/cm³ and are particularly effective in improving low-temperature impact resistance in automotive compounds and rigid packaging applications.

For film applications, specialized POE grades offer enhanced optical properties and flexibility. These grades typically feature very low crystallinity and controlled molecular weight distribution, resulting in excellent transparency and seal properties. The material's ability to improve impact strength without compromising optical clarity makes it invaluable in packaging applications.

Injection molding grades of POE are engineered with optimized melt flow characteristics, typically ranging from 2 to 20 g/10min. These grades ensure excellent processability while maintaining the desired flexibility and impact resistance in the final product. The carefully controlled molecular structure enables efficient processing and consistent product quality.

Industry Applications and Performance

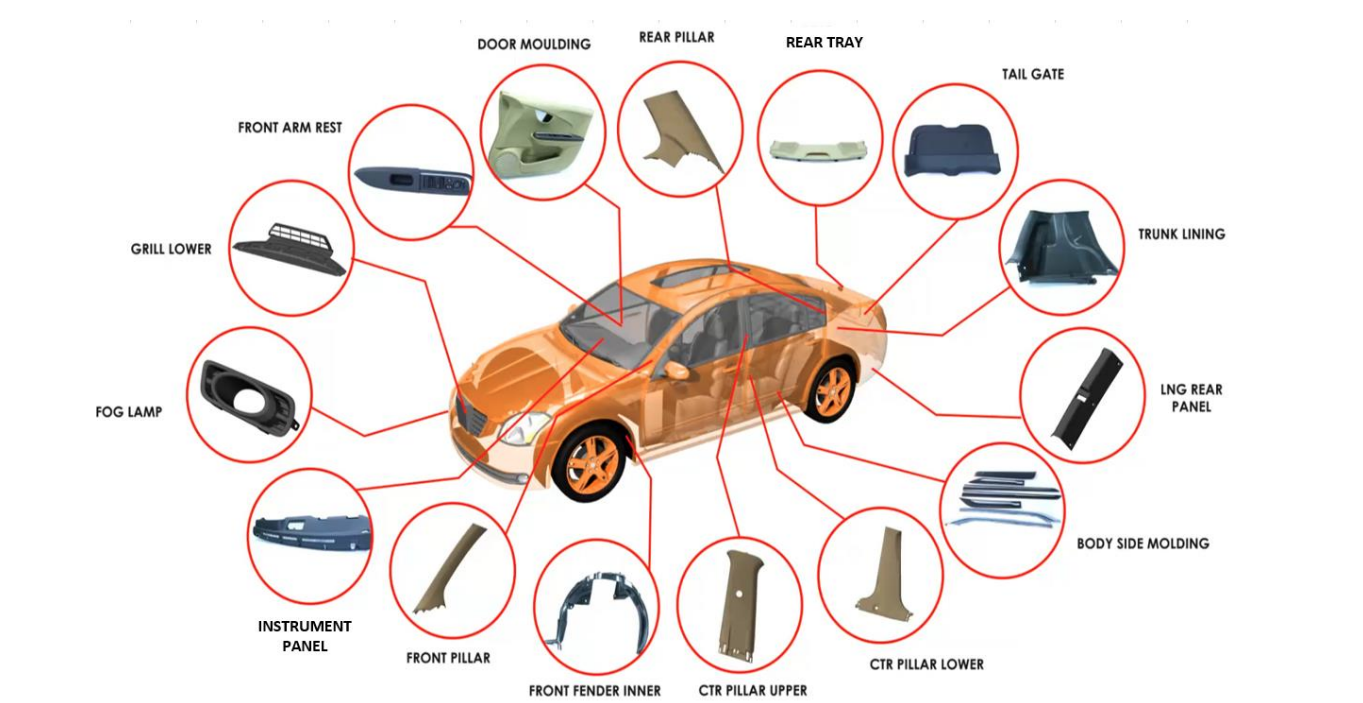

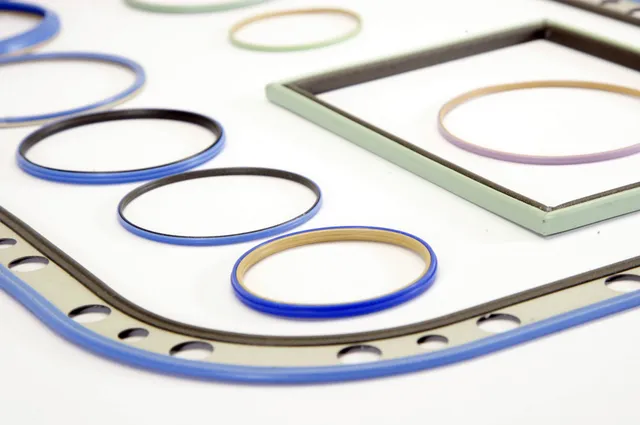

In the automotive sector, POE has revolutionized interior and exterior applications by providing enhanced softness and improved impact resistance to various components. The material's excellent low-temperature performance makes it particularly valuable in weather seals, interior trim, and bumper compounds. Its ability to maintain flexibility across a wide temperature range ensures reliable performance in demanding automotive applications.

The packaging industry benefits from POE's unique property profile in both flexible and rigid packaging applications. In flexible packaging, it enhances the seal strength and puncture resistance of films while improving their elastic recovery. For rigid packaging, POE serves as an effective impact modifier, enabling the development of tough, durable containers that resist cracking and breaking.

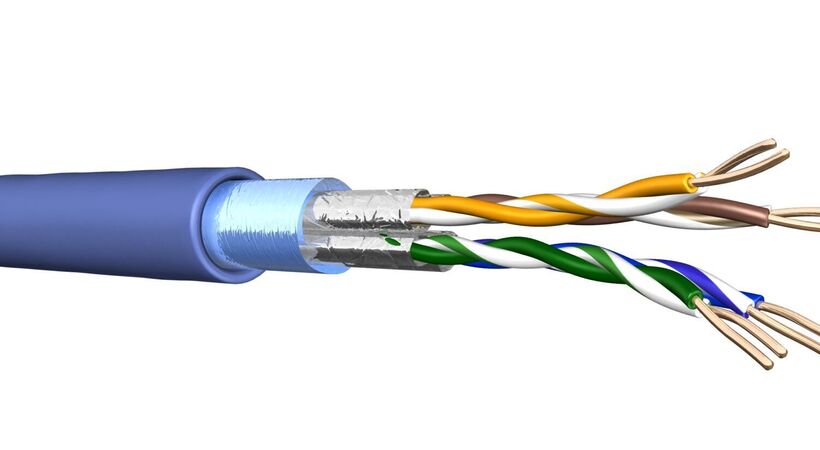

Wire and cable manufacturers utilize POE for its excellent electrical properties and flexibility. The material's compatibility with polyolefins makes it ideal for cable insulation and jacketing compounds, where it provides enhanced flexibility and improved stress crack resistance. Its thermal stability ensures long-term performance in both indoor and outdoor applications.

In the medical sector, POE grades meeting healthcare standards offer an excellent alternative to PVC in various applications. The material's purity, combined with its flexibility and sterilization resistance, makes it suitable for medical tubing, bags, and other healthcare products requiring soft, flexible characteristics.

Features

- Excellent flexibility and elasticity

- Superior low-temperature impact resistance

- High compatibility with polyolefins

- Controlled molecular weight distribution

- Outstanding processing characteristics

- Good thermal stability

- Excellent weathering resistance

- Low-temperature flexibility

- Enhanced optical properties

- Superior elastic recovery

Applications

Automotive interior and exterior parts

Automotive interior and exterior parts Flexible packaging films

Flexible packaging films Agricultural films

Agricultural films Wire and cable insulation

Wire and cable insulation Medical devices and tubing

Medical devices and tubing Consumer goods

Consumer goods Sealing systems

Sealing systems Sports equipment and footwear

Sports equipment and footwear Adhesive formulations

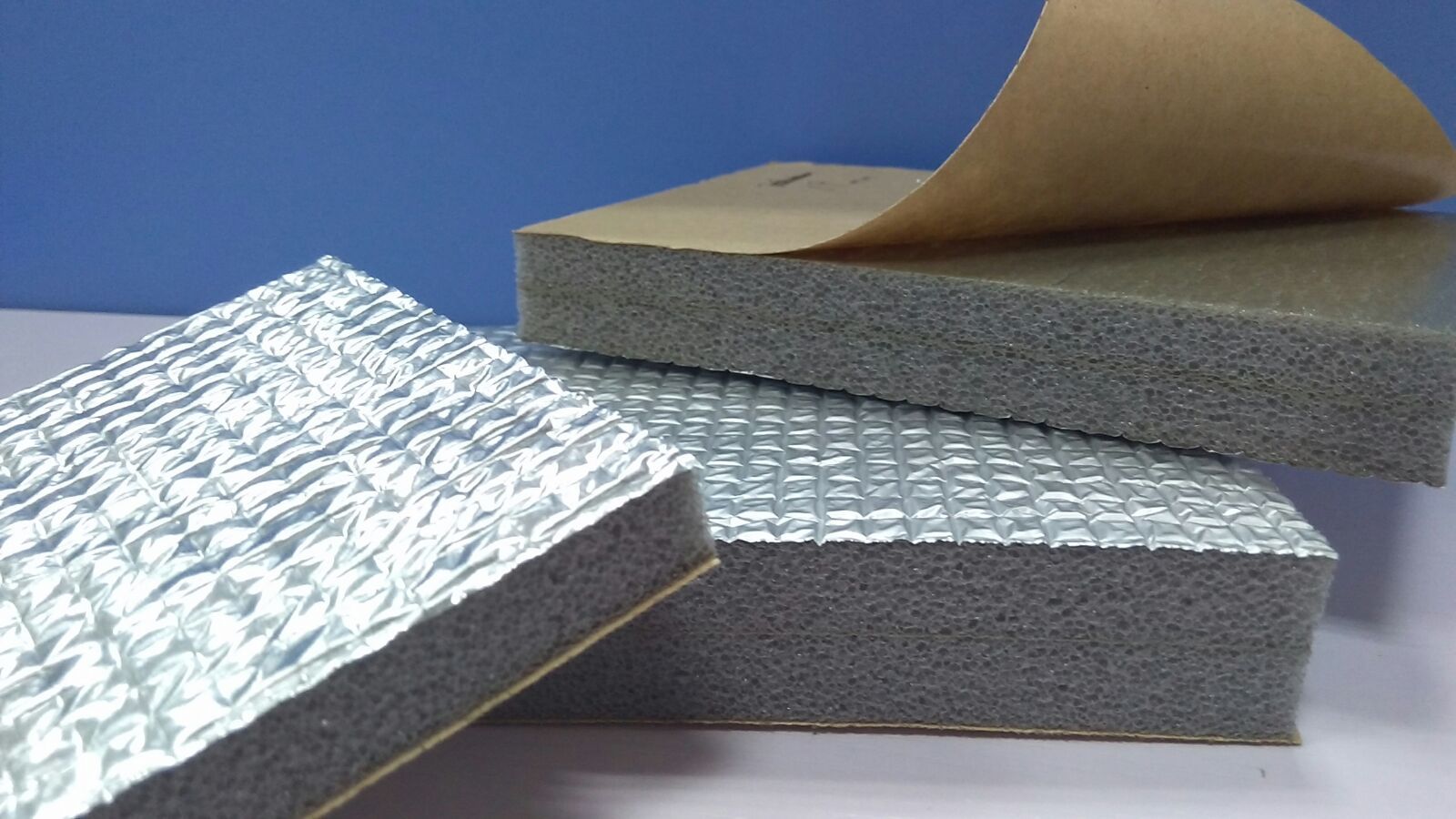

Adhesive formulations Foam applications

Foam applicationsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India