Polycarbonate : PC

Engineering Brilliance in Transparency and Impact

Transform your engineering applications with our Polycarbonate portfolio, where exceptional optical clarity meets outstanding impact resistance in a high-performance engineering thermoplastic.

Understanding PC (Polycarbonate)

Polycarbonate represents the pinnacle of engineering plastic design, built upon the elegant architecture of carbonate linkages connecting rigid bisphenol-A units. Picture a molecular structure where strong, rigid aromatic rings are connected by flexible carbonate bridges – like a suspension bridge where rigid towers are connected by flexible cables. This unique molecular design creates an amorphous polymer that combines glass-like transparency with incredible impact strength, even at extreme temperatures.

PC Classifications

Optical Grades

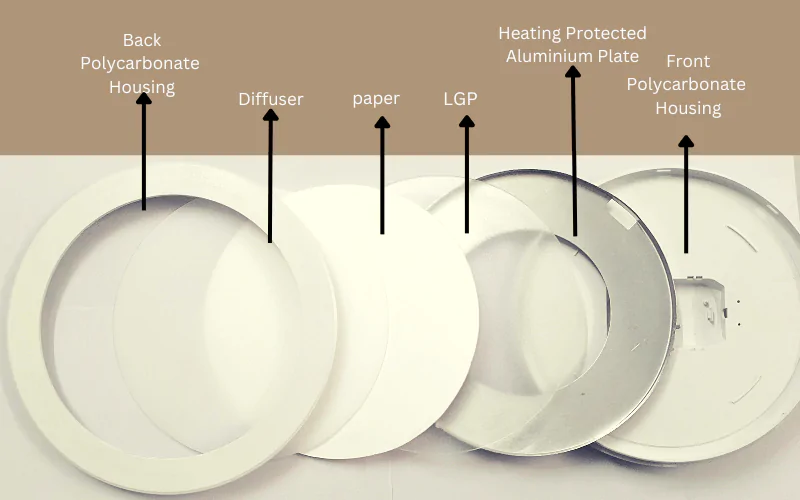

Our optical grade portfolio features melt flow rates (MFR) from 6 to 12 g/10min at 300°C, specifically engineered for applications demanding exceptional clarity and light transmission. These grades undergo special purification processes to achieve extraordinary transparency, often exceeding 89% light transmission. The carefully controlled molecular weight ensures excellent melt stability during processing, preserving optical properties even in complex molding operations.

General Purpose Grades

The general purpose grades showcase MFR ranges from 10 to 20 g/10min, providing balanced performance for everyday applications. These grades deliver the fundamental benefits of PC – high impact strength and good heat resistance – while offering excellent processability in injection molding operations. Their versatile property profile makes them ideal for applications ranging from consumer electronics to industrial components.

High Flow Grades

Engineered for complex or thin-wall applications, these grades feature MFR ranges from 22 to 35 g/10min. Their enhanced flow characteristics enable the filling of intricate mold details while maintaining PC's core mechanical properties. Think of these grades as having shorter molecular chains that flow more easily while still providing the interlocking strength that makes PC exceptional.

Flame Retardant Grades

Our flame retardant portfolio incorporates specially formulated additives while maintaining MFR ranges from 8 to 25 g/10min. These grades achieve UL94 V-0 ratings down to thin sections without compromising the fundamental properties of PC. The non-halogenated flame retardant systems ensure environmental compliance while providing robust fire protection.

UV-Stabilized Grades

Designed for outdoor applications, these grades combine UV stabilizers with MFR ranges from 10 to 22 g/10min. The advanced stabilization packages protect against yellowing and property degradation, extending service life in outdoor exposure. These grades maintain clarity and impact strength even after years of sun exposure.

Applications in Modern Industry

In the automotive industry, PC has revolutionized lighting design. Modern headlamp lenses showcase PC's unique combination of optical clarity and impact resistance. The material's ability to maintain these properties across extreme temperature ranges, from desert heat to arctic cold, makes it invaluable in automotive applications. UV-stabilized grades ensure these components maintain their clarity and performance throughout the vehicle's lifetime.

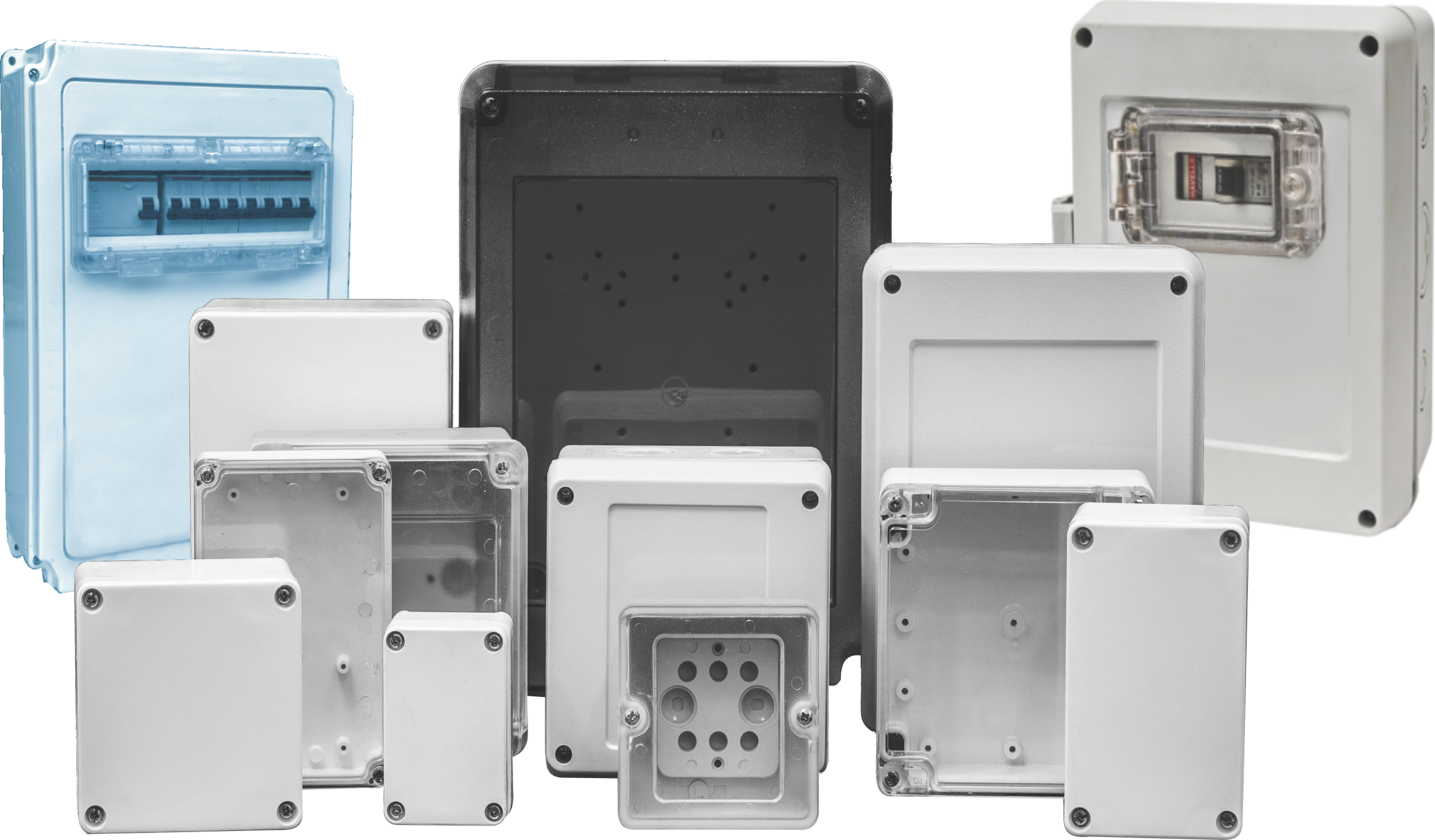

The electronics sector relies heavily on PC's exceptional property profile. From smartphone cases to laptop housings, PC provides the perfect balance of aesthetics and durability. Flame retardant grades create safe, robust housings for electronic devices, while high flow variants enable the production of increasingly thin and complex components that modern electronics demand.

In the medical field, PC's biocompatibility and sterilization resistance make it indispensable. From clear medical devices to sterilizable equipment housings, PC provides the reliability and clarity healthcare professionals depend on. The material's ability to withstand repeated sterilisation cycles while maintaining its properties ensures long-term performance in critical medical applications.

Features

- Exceptional impact strength

- Outstanding optical clarity

- Superior heat resistance

- Excellent dimensional stability

- Good electrical properties

- Robust flame resistance options

- Biocompatible grades available

- Wide processing window

Applications

Automotive lighting

Automotive lighting Medical devices

Medical devices Safety eyewear

Safety eyewear Electronic housings

Electronic housings Optical media

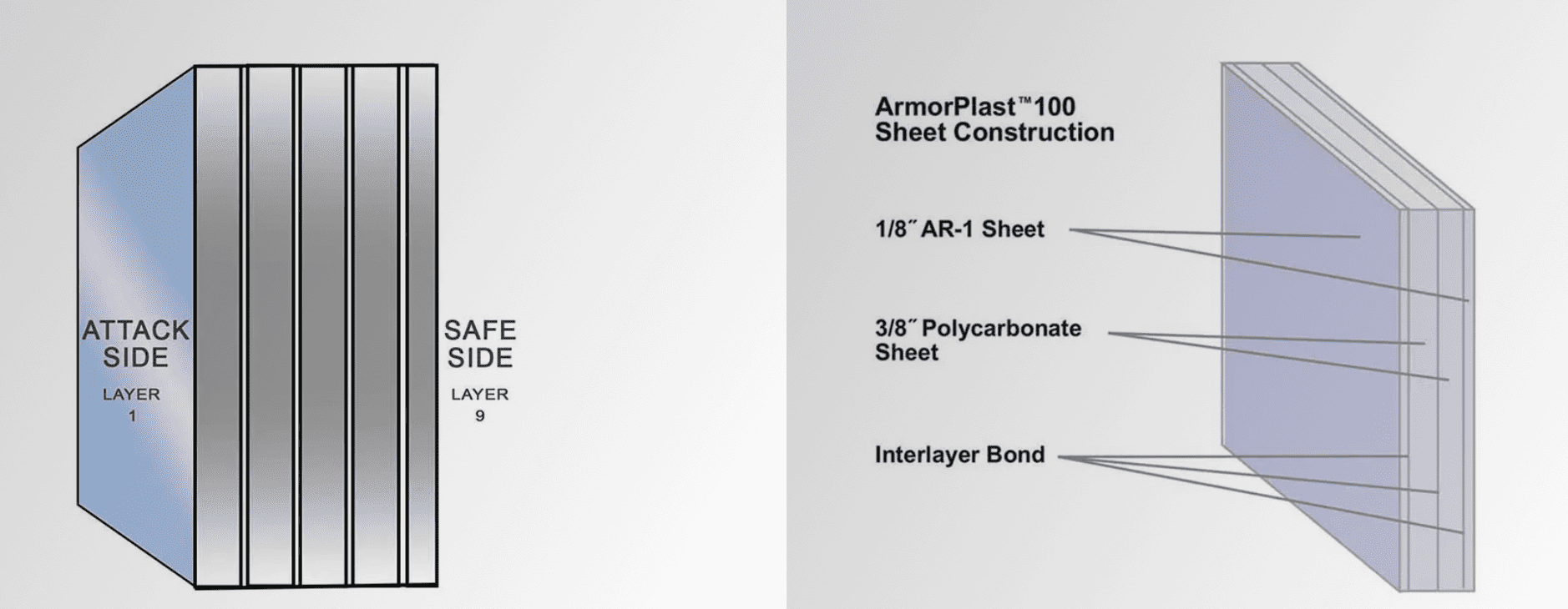

Optical media Security glazing

Security glazing Industrial machinery

Industrial machinery LED lighting components

LED lighting componentsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India