Polyethylene Terephthalate : PET

Engineering Clarity with Molecular Precision

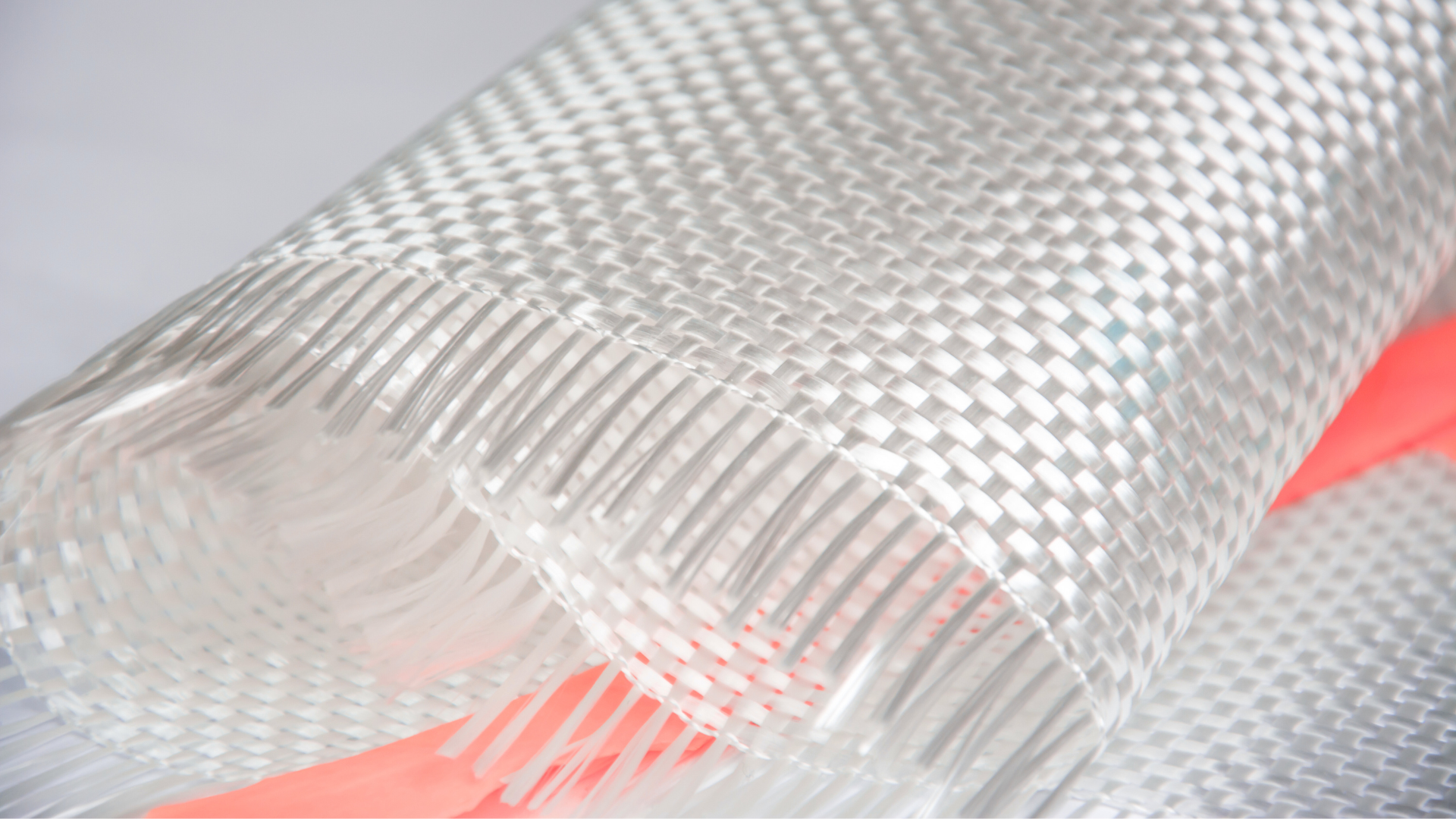

Transform your packaging and fibre applications with our Polyethylene Terephthalate portfolio, where exceptional clarity meets processing versatility in a sustainable polymer solution.

Understanding PET (Polyethylene Terephthalate)

Polyethylene Terephthalate represents an engineering marvel in polymer science, created through the precise condensation polymerisation of terephthalic acid and ethylene glycol. This unique molecular structure features rigid aromatic rings connected by flexible ester linkages, much like a string of pearls where each pearl (the aromatic ring) provides strength while the string (ester linkages) allows for precise alignment. When processed correctly, these molecules can arrange themselves into highly ordered crystalline regions or remain in an amorphous state, giving PET its remarkable versatility in both fiber and packaging applications.

PET Classifications

Bottle Grade Resins

General Purpose Bottle Grade

Our standard bottle grade PET features intrinsic viscosity (IV) ranges from 0.76 to 0.82 dL/g, optimized for conventional stretch blow molding processes. These grades provide the perfect balance of processability and container performance, ensuring excellent clarity and strength in beverage bottles while maintaining high production efficiency. The controlled crystallization kinetics enable wide processing windows in both preform injection and bottle blowing stages.

Hot-Fill Bottle Grade

Engineered for high-temperature applications, these grades offer IV ranges from 0.82 to 0.85 dL/g. Their enhanced crystallization characteristics provide superior heat resistance up to 85°C, making them ideal for hot-fill beverages and pasteurized products. The carefully controlled chain structure ensures excellent clarity even with higher crystallinity levels.

Fast Reheat Grades

These specialized grades incorporate infrared-absorbing additives while maintaining IV ranges of 0.76 to 0.82 dL/g. Their enhanced thermal absorption properties enable faster preform heating in the blow molding process, reducing energy consumption and increasing production efficiency without compromising bottle properties.

Fiber Grade Resins

Textile Fiber Grade

Our textile grades showcase IV ranges from 0.62 to 0.64 dL/g, specifically engineered for high-speed fiber spinning. These grades provide excellent uniformity in fiber production while ensuring the perfect balance of strength and elongation properties required for textile applications. Their controlled crystallization behavior supports efficient drawing and texturing processes.

Technical Fiber Grade

Designed for industrial applications, these grades feature higher IV ranges from 0.65 to 0.70 dL/g. The enhanced molecular weight provides superior strength and thermal stability, crucial for technical applications like tire cord and industrial belting. Their carefully controlled carboxyl end group content ensures excellent hydrolytic stability.

Film Grade

Our film grade PET offers IV ranges from 0.63 to 0.65 dL/g, optimized for both thin and thick film applications. These grades provide exceptional clarity and surface smoothness while maintaining excellent mechanical properties. Their controlled crystallization behavior ensures optimal processing in both cast and biaxially oriented film production.

Applications in Modern Industry

In the beverage packaging sector, PET has revolutionized how we package and transport liquids. From carbonated soft drinks to water bottles, PET provides the perfect combination of clarity, strength, and barrier properties. The material's ability to be processed into lightweight yet strong containers has transformed the beverage industry, reducing transportation costs while maintaining product integrity.

The textile industry relies heavily on PET fiber (polyester) for both fashion and technical applications. In apparel, PET creates everything from luxurious fabrics to high-performance sportswear. The material's excellent dimensional stability and durability, combined with its ability to accept dyes brilliantly, make it indispensable in modern textile manufacturing.

In technical applications, PET's high strength-to-weight ratio and dimensional stability create ideal solutions for industrial products. From tire reinforcement to conveyor belts, PET's combination of mechanical properties and chemical resistance ensures reliable performance in demanding environments.

Features

- Outstanding clarity and gloss

- Excellent barrier properties

- Superior mechanical strength

- Good chemical resistance

- Exceptional dimensional stability

- Wide processing window

- High recyclability

- Consistent quality

Applications

Beverage containers

Beverage containers Food packaging

Food packaging Textile fibers

Textile fibers Technical yarns

Technical yarns Packaging films

Packaging films Industrial strapping

Industrial strappingExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India