Polypropylene : PP

Engineering Versatility through Controlled Structure

Transform your manufacturing capabilities with our Polypropylene portfolio, where molecular architecture meets application versatility in creating tailored polymer solutions.

Understanding PP (Polypropylene)

Polypropylene represents a triumph in stereoregular polymerization, where precise catalyst control creates perfectly aligned methyl groups along the polymer backbone. This molecular orchestration allows us to control the polymer's crystallinity and properties through three distinct stereochemical arrangements: isotactic, where methyl groups align uniformly on one side; syndiotactic, with alternating positions; and atactic, featuring random orientation. Think of it as arranging building blocks – the way we position each block determines the entire structure's properties.

PP Classifications

Homopolymer Grades

Injection Molding Grades

Our injection molding portfolio spans MFI ranges from 2 to 70 g/10min. The lower MFI grades (2-8) excel in structural applications demanding high stiffness, while medium-flow grades (12-25) offer balanced properties for general-purpose molding. High-flow grades (30-70) enable ultra-fast cycling in thin-wall packaging applications, where every second counts in production efficiency.

Fiber Grades

Engineered specifically for fiber production, these grades feature MFI ranges from 20 to 35 g/10min. Their carefully controlled molecular weight distribution ensures excellent spinnability and drawability, crucial for producing everything from continuous filaments to spunbond nonwovens. The enhanced crystallization kinetics support high-speed fiber production while maintaining consistent fiber properties.

Raffia Grades

Our raffia grades showcase MFI ranges from 2 to 5 g/10min, optimized for high-speed tape extrusion. These grades combine excellent drawability with superior tensile strength, making them ideal for woven bags and industrial fabrics. Their enhanced UV stability packages ensure long-term outdoor performance.

Impact Copolymer Grades

High Impact Grades

Designed for demanding applications, these grades incorporate ethylene-propylene rubber phases within a homopolymer matrix, featuring MFI ranges from 4 to 25 g/10min. The rubber content varies from 10% to 25%, providing exceptional impact resistance even at low temperatures. These grades excel in automotive applications and industrial containers where toughness is paramount.

Clear Impact Grades

Our innovative clear impact grades achieve transparency through careful control of rubber particle size and crystallinity, with MFI ranges from 8 to 20 g/10min. They offer an excellent balance of clarity and impact resistance, making them ideal for visual packaging applications requiring toughness.

Random Copolymer Grades

Clarity Grades

These specialized grades incorporate ethylene units randomly within the PP chain, featuring MFI ranges from 2 to 35 g/10min. The interrupted crystallinity results in superior clarity and lower melting points, perfect for clear packaging and medical applications where aesthetics meet functionality.

Soft Touch Grades

Engineered for enhanced tactile properties, these grades offer higher ethylene content with MFI ranges from 8 to 25 g/10min. They provide a unique combination of softness and clarity while maintaining good heat resistance, ideal for consumer goods and specialty packaging.

Applications in Modern Industry

In the packaging sector, PP grades create everything from crystal-clear food containers to robust industrial packaging. The material's excellent balance of properties – from heat resistance to chemical stability – makes it ideal for hot-fill applications and microwaveable containers. The availability of clarified random copolymers has revolutionized clear packaging, offering glass-like transparency with the advantages of lightweight plastic.

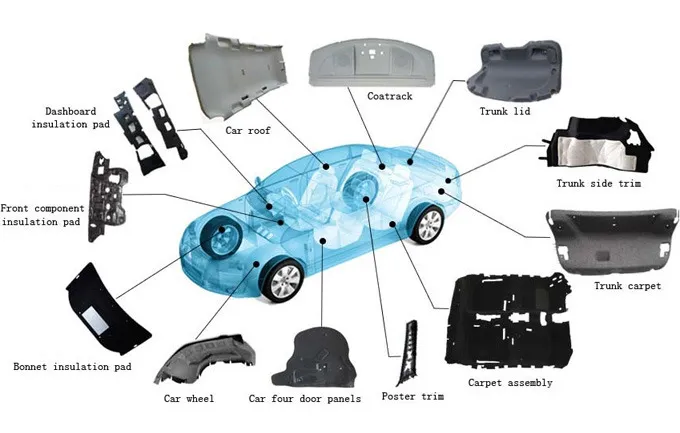

The automotive industry relies heavily on both homopolymer and impact copolymer grades. From interior trim to under-hood components, PP provides the perfect balance of properties and processability. Impact grades ensure bumper components maintain toughness in cold weather, while high-flow homopolymers create intricate interior parts with excellent surface finish.

In the medical field, PP's exceptional purity and stability make it the material of choice for syringes, diagnostic devices, and medical packaging. Random copolymer grades provide the clarity needed for visual inspection, while their enhanced sterilization resistance ensures product safety and reliability.

Features

- Outstanding heat resistance

- Excellent chemical stability

- Superior balance of stiffness and impact

- Low density for lightweight parts

- Enhanced processability

- Good surface finish

- Exceptional stress crack resistance

- Cost-effective performance

Applications

Packaging containers

Packaging containers Automotive components

Automotive components Medical devices

Medical devices Industrial containers

Industrial containers Textile fibers

Textile fibers Household appliances

Household appliances Laboratory equipment

Laboratory equipment Consumer goods

Consumer goodsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India