At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis

Butyl Rubber : IRR

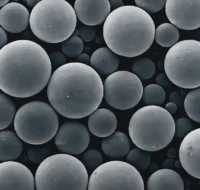

Calcium Carbonate : CaCO3

Chlorinated Paraffin Wax : CPW

Dibutyl Phthalate : DBP

Dioctyl Phthalate : DOP

Dioctyl Terephthalate : DOTP

High Impact Polystyrene : HIPS

Online store of household appliances and electronics

Then the question arises: where’s the content? Not there yet? That’s not so bad, there’s dummy copy to the rescue. But worse, what if the fish doesn’t fit in the can, the foot’s to big for the boot? Or to small? To short sentences, to many headings, images too large for the proposed design, or too small, or they fit in but it looks iffy for reasons.

A client that’s unhappy for a reason is a problem, a client that’s unhappy though he or her can’t quite put a finger on it is worse. Chances are there wasn’t collaboration, communication, and checkpoints, there wasn’t a process agreed upon or specified with the granularity required. It’s content strategy gone awry right from the start. If that’s what you think how bout the other way around? How can you evaluate content without design? No typography, no colors, no layout, no styles, all those things that convey the important signals that go beyond the mere textual, hierarchies of information, weight, emphasis, oblique stresses, priorities, all those subtle cues that also have visual and emotional appeal to the reader.