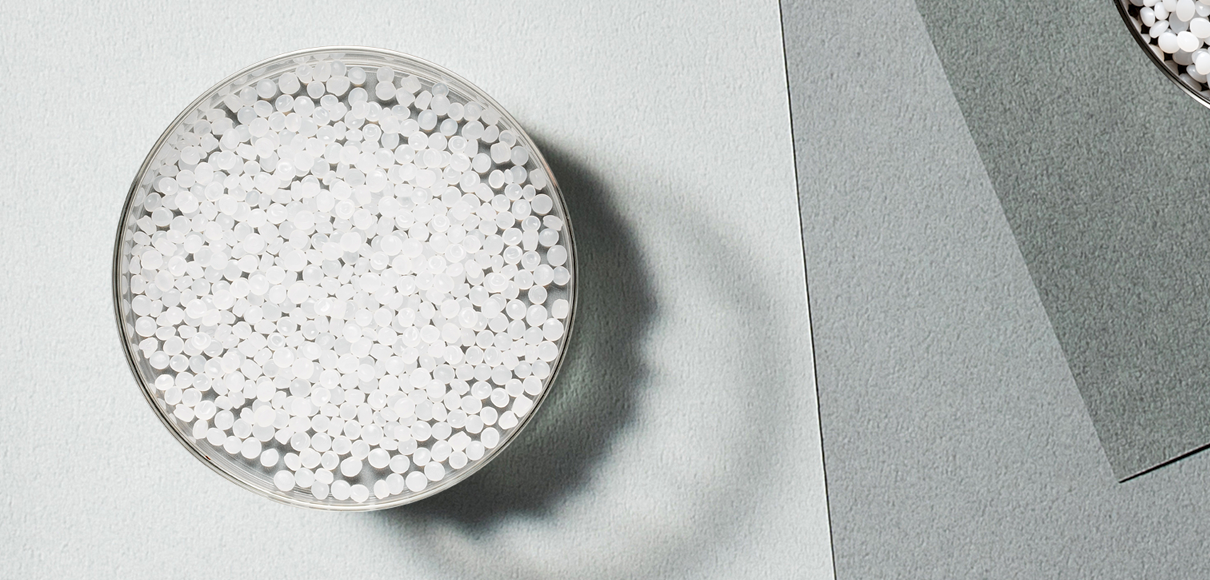

High-Density Polyethylene : HDPE

Engineering Strength into Everyday Solutions

Transform your manufacturing excellence with our High-Density Polyethylene grades, engineered to deliver superior strength and versatility across diverse applications.

Understanding HDPE (High-Density Polyethylene)

High-Density Polyethylene stands as a testament to advanced polymer engineering, characterized by its linear molecular structure with minimal branching. This unique molecular architecture results in higher density, creating a polymer that combines exceptional strength with remarkable processability. Unlike its lower-density cousins, HDPE's tightly packed molecular chains provide enhanced mechanical properties while maintaining excellent chemical resistance.

HDPE Classifications

Blow Molding Grades

Our blow molding HDPE grades span MFI ranges from 0.2 to 0.8 g/10min, carefully engineered for optimal parison formation and consistent wall thickness distribution. The lower MFI variants excel in large container manufacturing, while the higher end serves smaller packaging needs. Each grade ensures perfect balance between melt strength and environmental stress crack resistance (ESCR), crucial for containers holding various chemicals and household products.

Injection Molding Grades

Designed for efficiency and precision, our injection molding grades feature MFI ranges from 2 to 20 g/10min. The higher flow grades (MFI 8-20) excel in thin-wall applications and intricate parts, while medium flow grades (MFI 2-8) provide enhanced mechanical properties for durable goods. These grades offer excellent dimensional stability combined with superior surface finish.

Pipe Grades (PE63, PE80, PE100)

Our pipe grade classifications follow international standards based on Minimum Required Strength (MRS). PE63 grades serve basic water supply needs, PE80 offers enhanced pressure resistance, while PE100 represents the pinnacle of pipe grade technology with exceptional long-term strength. All grades feature MFI ranges between 0.2 to 0.5 g/10min, ensuring optimal extrusion characteristics and weld ability.

Film Grades

Specialized film grades with MFI ranges of 0.05 to 0.15 g/10min deliver exceptional strength and process stability for high-speed film production. These grades incorporate precise levels of antioxidants and processing aids to ensure trouble-free production of thin yet strong films, ideal for heavy-duty bags and industrial packaging.

Raffia Grades

Our raffia grades, featuring MFI ranges from 0.3 to 3.0 g/10min, are engineered for high-speed tape extrusion and weaving operations. These grades provide the perfect balance of drawability and tensile strength, essential for producing robust woven sacks and industrial fabrics.

Applications in Modern Industry

HDPE's versatility shines across numerous industrial applications. In the packaging sector, blow molding grades create everything from milk bottles to industrial chemical containers. The material's excellent ESCR properties ensure product integrity even with aggressive contents, while its natural translucency allows for creative design possibilities.

The pipe industry relies heavily on HDPE's superior properties. PE100 pipes now carry water and gas across continents, replacing traditional materials with their superior flexibility and corrosion resistance. Modern infrastructure development increasingly depends on these grades for their exceptional long-term performance and ease of installation.

Film grade HDPE has revolutionized the packaging industry, particularly in heavy-duty applications. These films combine incredible strength with minimal material usage, creating sustainable packaging solutions for everything from construction materials to agricultural products. The material's excellent moisture barrier properties make it indispensable in protecting goods throughout the supply chain.

Features

- Exceptional strength-to-density ratio

- Superior environmental stress crack resistance

- Excellent chemical resistance

- Wide processing window

- Outstanding impact strength

- High tensile strength

- Natural UV resistance potential

- Excellent moisture barrier

Applications

Agricultural products

Agricultural products Heavy-duty containers

Heavy-duty containers Automotive fuel tanks

Automotive fuel tanks Storage tanks

Storage tanks Woven sacks

Woven sacks Industrial films

Industrial films Packaging containers

Packaging containers Pressure pipes and fittings

Pressure pipes and fittingsExperience seamless supply chain solutions with JITSY. Your trusted partner for Just in Time Supply needs. Optimise operations today!

Quick Links

Contact

- connect@jitsy.in

- +91 9711562699

-

Salcon Rasvilas

Saket, New Delhi

India